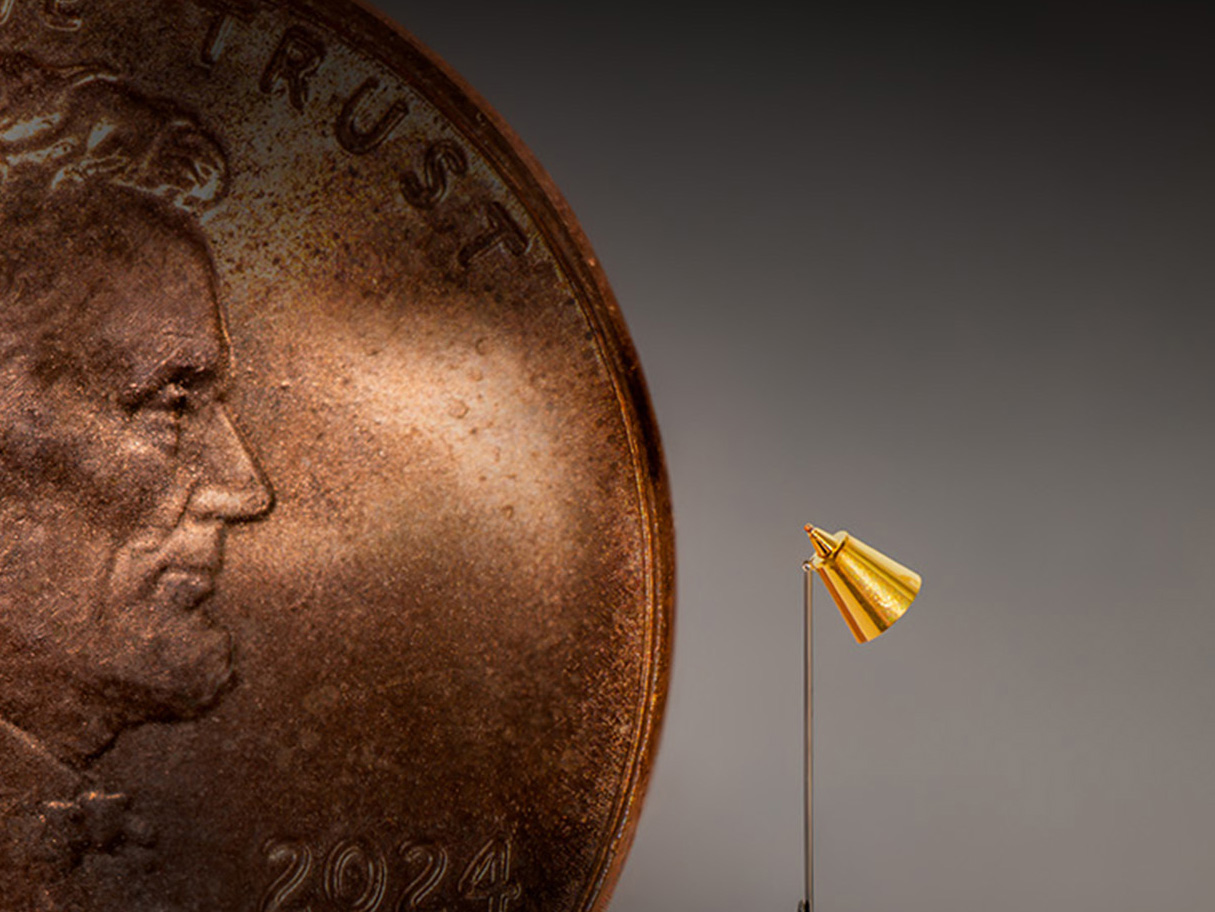

Target Development & Fabrication

To meet the demands of our broad user base, LLE’s Target Fabrication Facility manufactures over 2500 precision targets per year, while continuing to develop new target-production methods and conducting routine metrology of targets at micron resolution. The facility is home to various types of microscopy (scanning electron, atomic force, confocal, stereo, compound, and 3D x-ray tomography), a world-leading two-photon polymerization 3D printer, and multiple assembly stations.

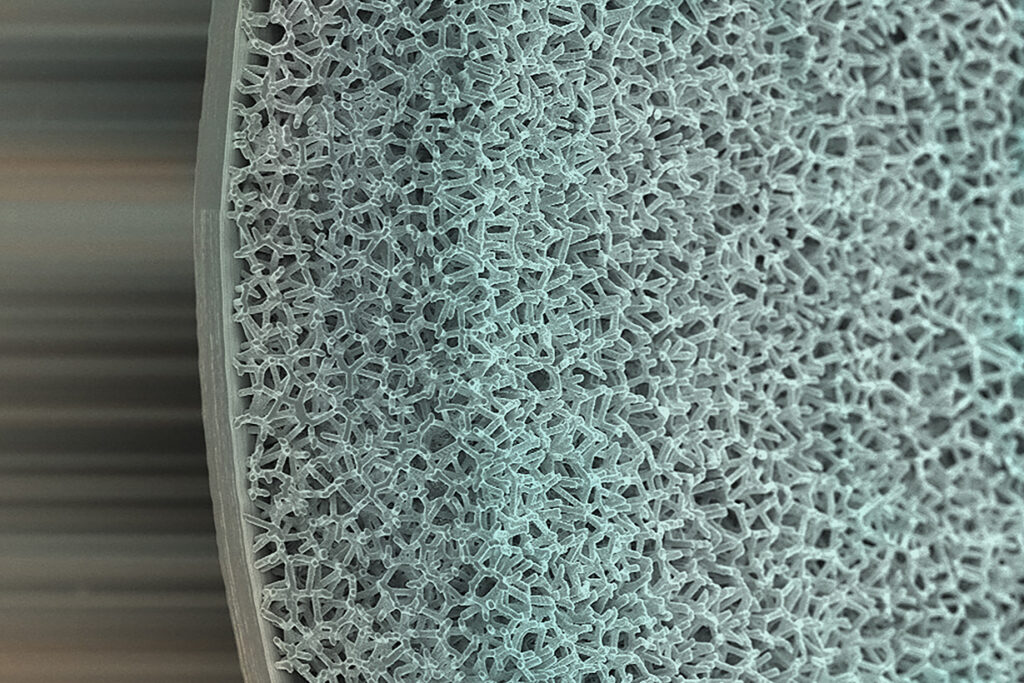

Additive Manufacturing: Custom Foams at the Microscale

LLE’s two-photon polymerization printer enables the creation of plastic shells with tailored foam structures at nanometer resolution. This method allows for precise control over radial density profiles, surface smoothness, and filament thickness—paving the way for more advanced implosion target designs.

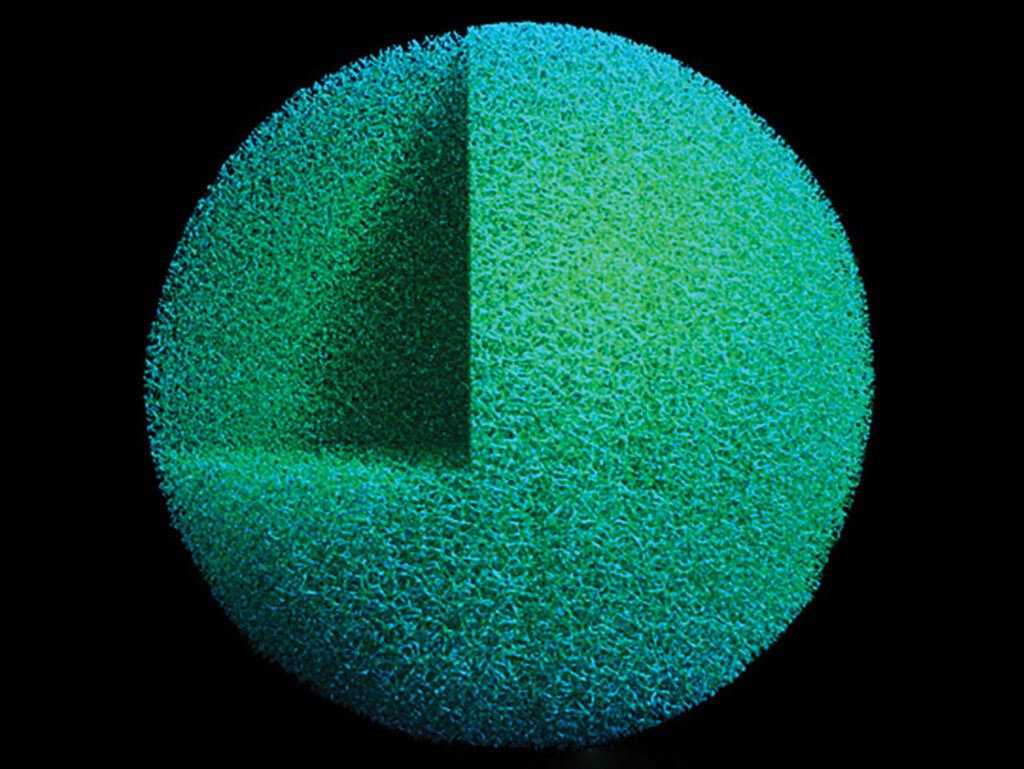

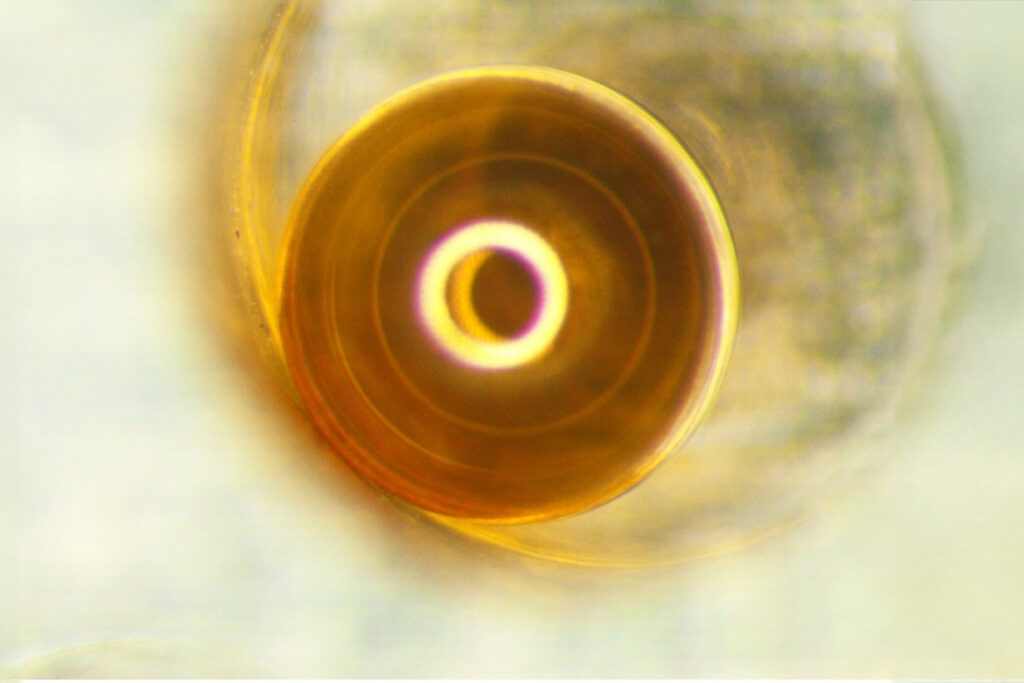

CARS Imaging: Probing the Molecular Structure of Transparent Targets

In collaboration with the University of Nebraska–Lincoln, LLE uses coherent anti-Stokes Raman spectroscopy (CARS) to map the internal chemistry and structure of plastic and cryogenic targets with submicrometer resolution—revealing voids, glue layers, and isotope distribution critical to experimental accuracy.

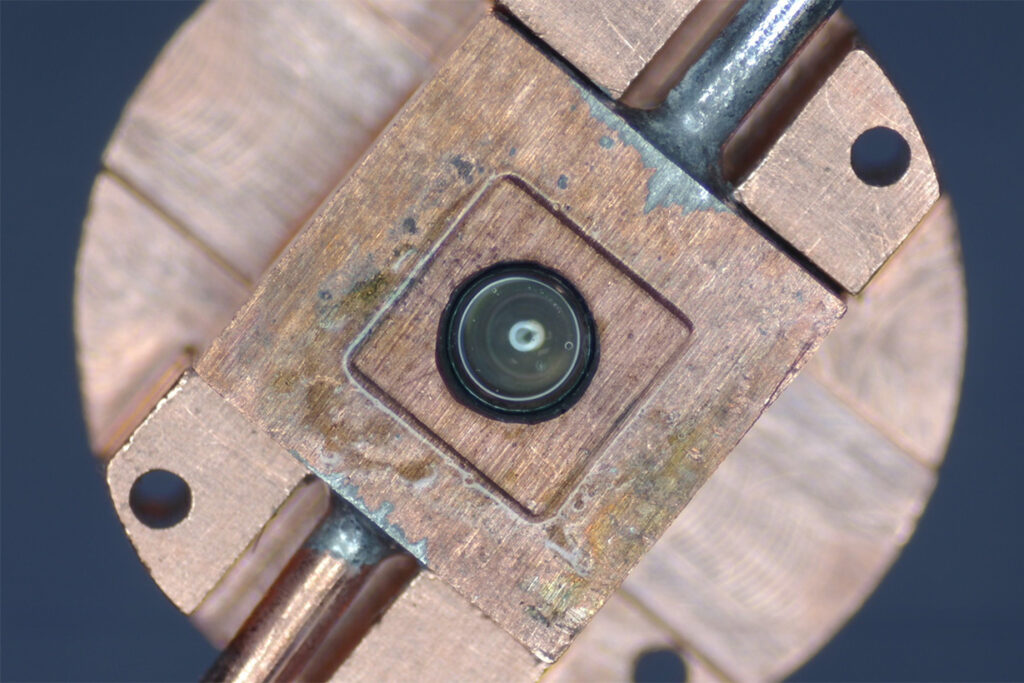

X-Ray Tomography: Peering Inside Opaque Targets

LLE’s SKYSCAN 2214 3D x-ray microscope provides non-destructive imaging of complex target structures, including multilayer foils and foam spheres. This high-resolution tool helps researchers detect internal defects and ensure the quality of fusion targets before they are used in experiments.

Precision at Scale

The Target Fabrication Group produces more than 2,500 high-precision targets annually to support experiments at the OMEGA Laser Facility. These include plastic shells, cryogenic fuel layers, and intricate foam assemblies fabricated with the highest standards of accuracy.

Collaborative Innovation with General Atomics

For over 30 years, LLE and General Atomics (GA) have partnered to advance the science and precision of target fabrication for high-energy-density physics. GA fabricates key target components and maintains a dedicated on-site team at LLE to support design collaboration, metrology, and delivery for OMEGA and OMEGA EP campaigns. This long-term collaboration continues to drive innovation in capsule design, cryogenic fuel systems, and defect detection, enabling increasingly complex experiments for national laboratories and academic researchers.