Optical Manufacturing

Our state-of-the-art facilities and highly-trained technicians fabricate lenses, mirrors, and other optical components with exacting tolerances using advanced materials and processes. This in-house manufacturing expertise ensures that every optical element meets stringent quality and performance standards.

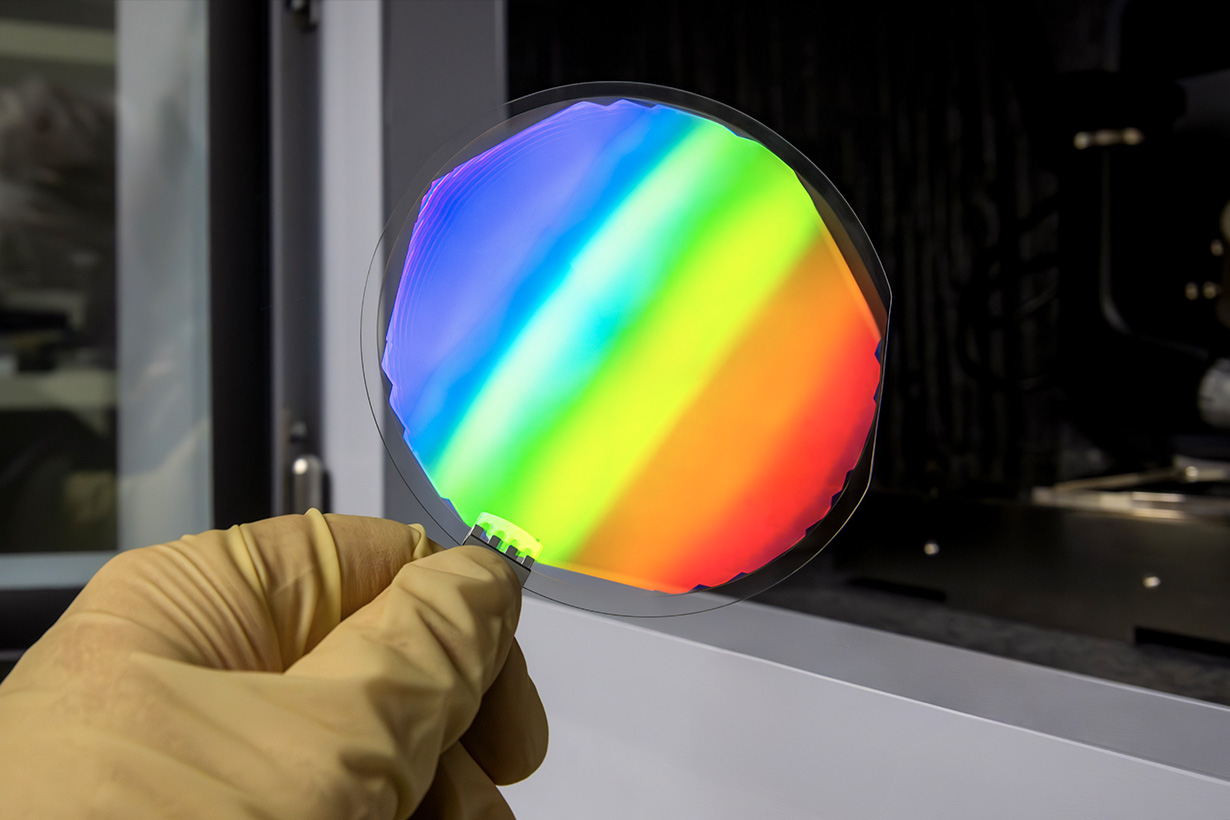

- Design and manufacture multilayer dielectric coatings for polarizers, beam splitters, and highly reflective mirrors as well as anti-reflection coatings for lenses and other transmissive optics

- Produce coatings and assemble deformable mirrors

- Integrate and mount optics into mechanical assemblies

- Manufacture liquid crystal polarizers and liquid crystal waveplates

- Evaluate optics and materials to measure performance and characterize their properties

- Develop new processing methods for optical materials in order to fabricate components with enhanced resistance to laser damage while controlling the properties of light

- Conduct optics inspection, cleaning, replacement, and configuration changes required for laser shot operations