Cryogenic & Tritium Facility

Advanced tritium management and cryogenic target development focused on safety, reliability, and uniformity

Consistent, Uniform Ambient & Cryogenic Targets

LLE operates one of the nation’s only cryogenic target production programs, uniquely capable of meeting the demanding density and uniformity requirements needed for advanced fusion experiments. Through its Cryogenic and Tritium Facility (C&TF), the laboratory produces, fills, and mounts more than 100 deuterium–tritium (DT) targets each year—supporting both LLE researchers and external collaborators.

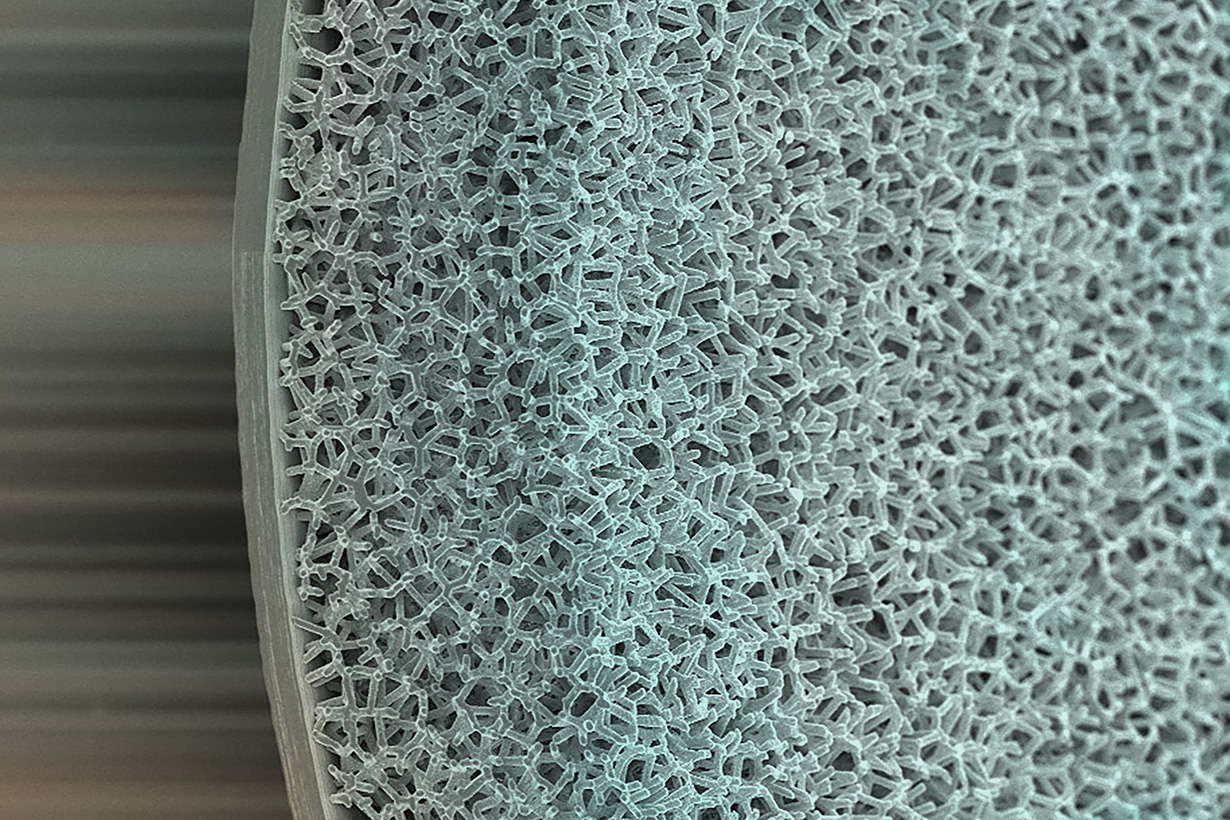

LLE’s cryogenic program prepares fusion targets by filling plastic shells with a precise mixture of deuterium and tritium gas at pressures up to 1000 atm. These targets are cooled to –255°C (18 K), where advanced ice-layering techniques developed at LLE create smooth, highly uniform fuel layers inside each capsule.

Once filled, the targets are carefully transferred onto mobile transport carts (MCTCs), where final ice layering is performed before they are brought to the Omega Laser Facility. Every cryogenic target undergoes rigorous inspection for shape, fuel layer thickness, and surface quality, with LLE routinely achieving submicron levels of smoothness. Robotic handling systems and MCTCs maintain cryogenic and vacuum conditions throughout transport and insertion, ensuring that each target arrives at the chamber in optimal condition for experiments.

Target R&D, Fabrication

Improving consistency and uniformity within each layer enables breakthroughs in inertial confinement fusion and high-energy-density science.

Safe, Reliable Tritium Handling

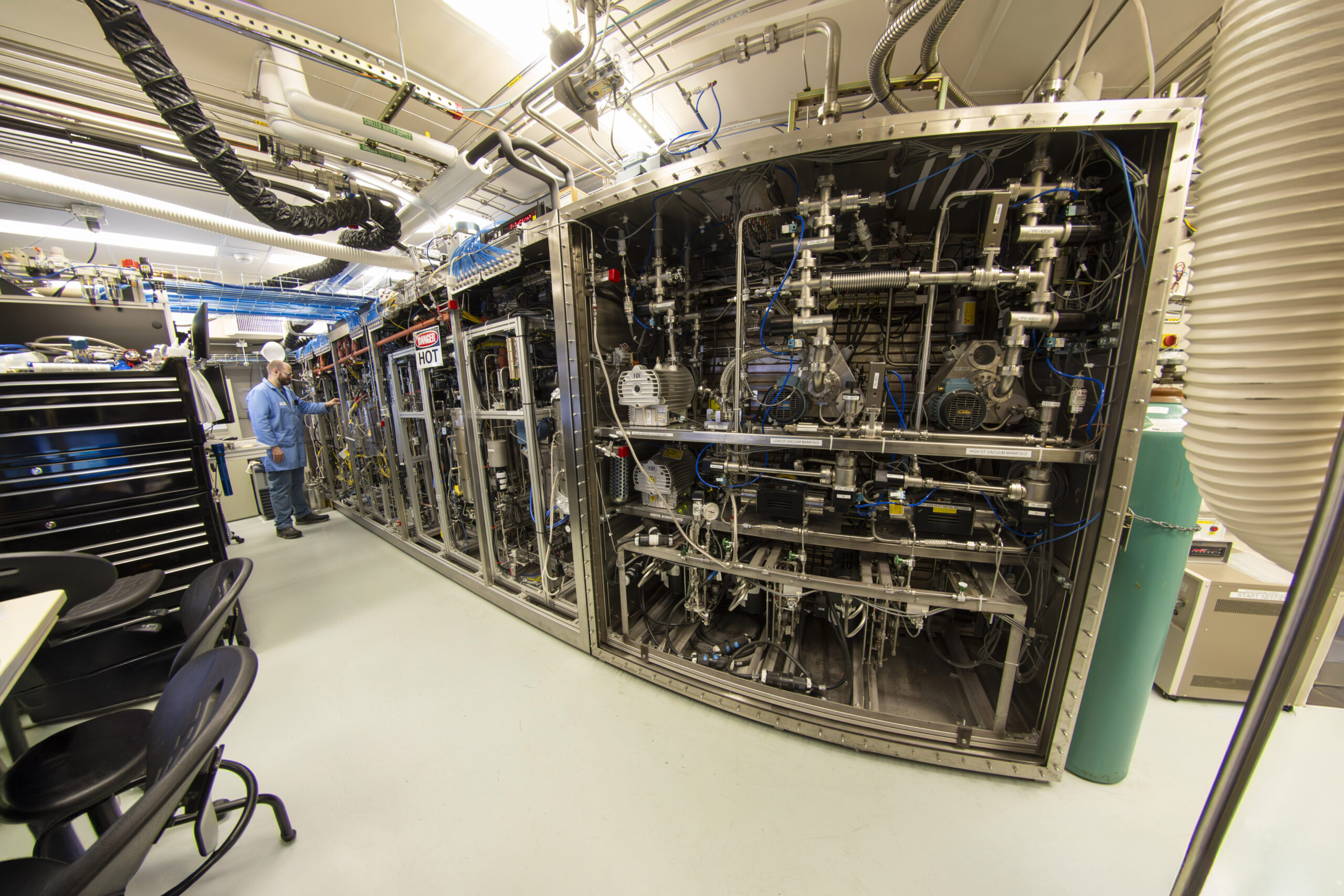

Tritium is both a valuable resource and a material that requires careful management. Our tritium facility is purpose-built for the safe storage, purification, and use of tritium gas.

We maintain a controlled inventory, operate with multiple layers of safety, and ensure that our processes meet or exceed all regulatory requirements.

-

Controlled Inventory: Licensed to handle up to 15,000 Ci of tritium, we typically operate with approximately 1 g in active use. This ensures both flexibility for research and strict safety oversight.

-

Specialized Equipment: Our facility is equipped with uranium beds for tritium storage, palladium filters for purification, and gloveboxes for safe, contained handling.

-

Emission Control: We use multistage tritium removal systems and real-time monitoring to keep tritium emissions well below regulatory limits.

-

Precision Filling: Our Tritium Fill Station (TFS) allows for accurate loading of DT gas into target capsules. Any tritium that escapes is captured and recovered, minimizing waste.

-

Continuous Improvement: We are committed to ongoing upgrades, including advanced tritium recovery systems and isotope separation, to further enhance safety, efficiency, and sustainability.

An Integrated & Controlled Approach

All tritium handling, target filling, and cryogenic layering operations are conducted within the controlled environment of our tritium facility. This integrated approach minimizes tritium loss, enhances safety, and ensures that each target is produced to the highest standards.

For our partners, this means a streamlined workflow from tritium management to target delivery, reducing turnaround time for more efficient experiments.